Lift-

Swivel combination

Products

Rotary actuators

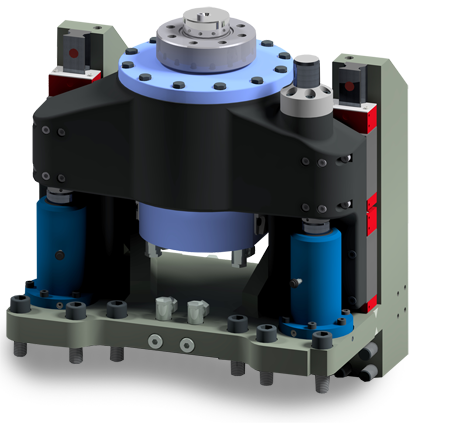

LIFT-SWIVEL UNITIn many cases, today’s machine tools are no longer equipped with a fixed clamping surface on a machine table, but have interchangeable workpiece carriers, so-called pallets, on which workpieces are fixed directly or with the help of devices. This enables preparatory set-up outside the machine and thus reduces set-up and non-productive times.

The Hense Systeme pallet changers of the HPW series perform the task of exchanging the pallet on the set-up station for the pallet in the processing area.

They have a linear and a rotary drive axis, which can be controlled independently of each other and realize the movement sequence required for a pallet change, lifting – 180° swivelling – lowering. The two axes can be arranged in series or parallel to each other.

By adding further components to the drive axes, such as a motorized rotatable loading station with integrated media interface and clamping hydraulics for clamping the pallet, a body for holding the axes and the loading station, valve and control technology, the pallet changer becomes a high-quality and functional assembly.

Regardless of the arrangement of the drive axes in relation to each other, the Hense Systeme pallet changers can be positioned in front of the machine bed as a stand-alone system or can be fixed to the machine bed while incorporating it. In this way, the Hense Systeme pallet changer machine tools adapt optimally to the conditions of the machine tool.

Product overview

We are happy to help you

Do you have any further questions?