Quality is our top priority

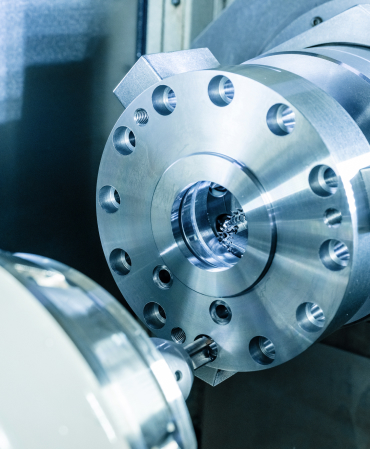

Complaint rate: 0.02 percentAt its Bochum site, Hense operates a state-of-the-art production facility in which the latest CNC machines are used to manufacture precise parts for hydraulic rotary actuators. Experienced specialists ensure that every detail is perfectly executed to meet the highest quality standards. Every manufactured part undergoes strict quality checks to ensure that it meets 100% of our and our customers’ requirements. The result: the complaint rate for all products delivered is 0.02%.

Contact us

Your production benefits with Hense

In a nutshellPrecision

Thanks to state-of-the-art CNC technology, Hense achieves maximum precision in the production of every single component.

Efficiency

The optimized manufacturing processes enable fast and cost-efficient production of high-quality products.

Flexibility

Hense offers customers the flexibility to meet individual requirements and provide customized solutions.

Innovation

Hense continuously invests in research and development in order to offer its customers innovative solutions.

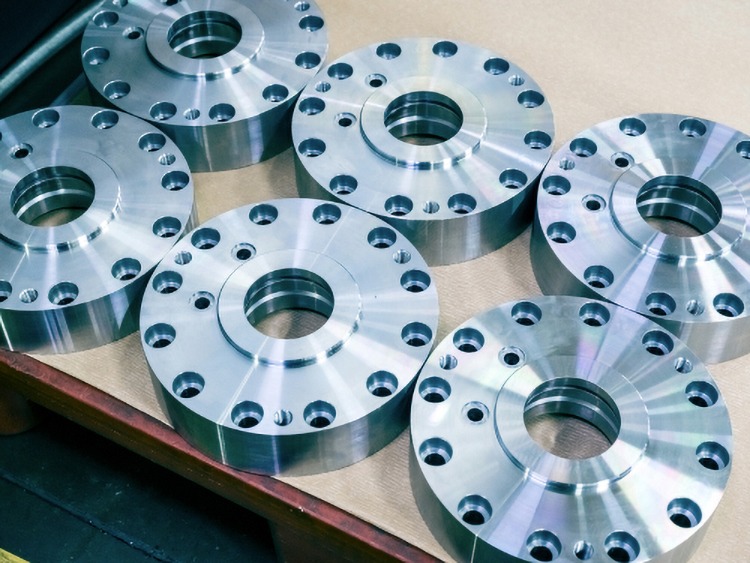

CNC manufacturing and metalworking

Our CNC production facilities make it possible to manufacture precise and complex parts with maximum efficiency. From machining to surface treatment, we can rely on state-of-the-art technology and experienced specialists. And with this duo, we produce products of the highest quality.

Component assembly

In our component assembly department, the previously manufactured parts are assembled into complete units. To ensure that each assembly meets the highest quality standards and functions optimally, we also work with the utmost precision and care.

Testing and quality assurance

In our component assembly department, the previously manufactured parts are assembled into complete units. To ensure that each assembly meets the highest quality standards and functions optimally, we also work with the utmost precision and care.

Test department

After assembly, all products are subjected to a comprehensive functional test in our test department to ensure that they can withstand the demands of real operating conditions. Only products that pass our strict test procedures leave our production facility and are delivered to our customers.

For individual advice

we are at your disposal

Do you have any further questions?