Precisely fitting drives for your movement

You know what needs to be moved – we know how to turn it into a functioning solution. Hense Systeme supports designers, planners and technical purchasers in implementing a wide range of movement tasks safely, efficiently and precisely. Especially when standard solutions reach their limits. Because we focus on movement, which makes us a strong partner for many demanding industries. We think beyond applications, provide advice at eye level and supply rotary actuators that are precisely tailored to your requirements.

- Personal support from experienced experts

- Complaint rate of only 0.02 %

- Short delivery times thanks to in-house production

- High reliability in continuous operation

- Smooth installation thanks to practical design

- Rapid assistance on site if required

Four rotary actuators Many options for your movement

Typical areas of application

Ideal for many applications

General mechanical engineering

General mechanical engineering

General mechanical engineering is often about robust, cost-efficient solutions – with high repeat accuracy and a long service life. This is exactly where rotary actuators from Hense Systeme come in. With a modular system, decades of experience and in-house production, we create drives that can be seamlessly integrated into existing concepts. Our motors are suitable for a wide range of installation positions, are low-maintenance and ready for immediate use. We offer tailor-made special solutions for individual requirements – from a quantity of 1. This keeps your machine economical and efficient without compromising on quality and precision.

Automation

Automation

Automated processes require precise, repeatable movements with low susceptibility to faults. Rotary actuators from Hense Systeme reliably meet these requirements. Thanks to their compact design, flexible controllability and suitability for integration, they can be easily incorporated into existing automation solutions. The low-maintenance design ensures high availability, while the high manufacturing quality ensures maximum running performance. For special applications, we develop individual variants of our assemblies, precisely tailored to the cycle time, force curve and control environment. Cooperation with our customers and in-house development ensure that every solution is technically sound, economically feasible and quickly available.

Special machine construction

Special machine construction

Special machine construction requires customized technology that can be adapted precisely to the application. At Hense, the focus is on the customer’s individual solution: after clarifying all interfaces, we develop optimal, precisely tailored concepts. In addition to standard actuators, we offer specialized rotary actuators, which we can implement from a quantity of 1. Thanks to sound technical advice and our complete in-house development, we create solutions that make optimum use of the available installation space, work reliably and can be integrated smoothly. High precision, long service life and easy handling are a matter of course for us. We implement even complex requirements economically – thanks to our modular design and many years of experience in a wide range of industry projects.

Machine tool construction

Machine tool construction

Dynamics, precision and absolute reliability are what count in machine tool construction. Rotary actuators from Hense Systeme deliver exactly that – especially with high load changes. Our drives can be easily integrated into complex machine concepts and meet the highest requirements for motion control, positioning accuracy and continuous operation. Series solutions are available in various sizes, but can be customized at any time. The components are robust, low-maintenance and technically tested. Thanks to our short development paths and binding delivery times, we ensure fast and uncomplicated commissioning in your environment.

Increased safety requirements

Increased safety requirements

In sensitive areas where maximum safety is required, rotary actuators from Hense Systeme offer tested and robust technology. On request, they can be certified for potentially explosive zones or designed for seawater requirements, for example. Each system is adapted precisely to the requirements and carefully tested before delivery. Most of the production takes place in-house, which allows us to guarantee not only quality, but also delivery stability, vertical integration and maximum control over the process.

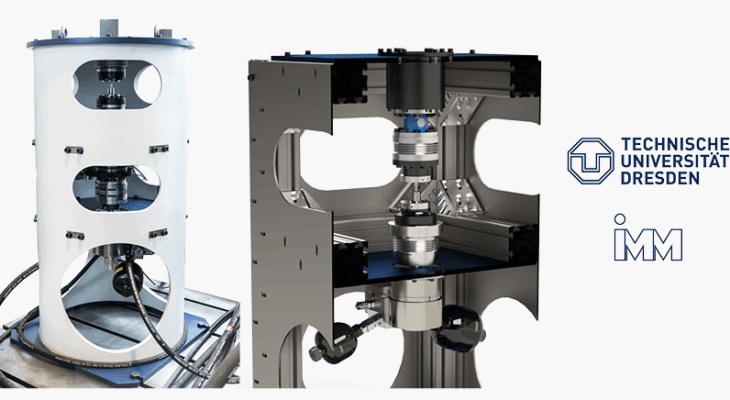

Test bench technology

Test bench technology

In testing technology, reproducible movements, precise control and high repeat accuracy are crucial. Hense Systeme develops rotary actuators that reliably meet these requirements. Our solutions are designed for highly dynamic test cycles and enable precise, documentable motion sequences. They can be flexibly adapted to test environments and function stably and safely even under intensive use.

The motors are equipped with the appropriate accessories and delivered tailored to the respective application. For optimum function and completion of the system, Hense Systeme also offers associated components such as rotary encoders, pulsation accumulators or torsionally rigid couplings. Whether for simple series test benches or highly specialized systems: we advise you individually, deliver quickly and guarantee technical quality that you can rely on.

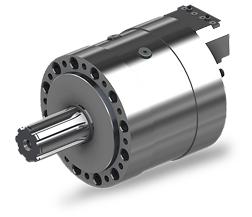

Custom rotary actuators

Special solutions that fit your movement exactlyWhen standard solutions do not work, our greatest strength comes into play: we develop rotary actuators that are application-independent and precisely tailored to your requirements. Thanks to decades of experience, sound advice and modular basic solutions, we deliver your individual drives quickly, cost-effectively and reliably on the desired date – and all this from a quantity of 1.

For maximum quality, we test the specific rotary actuator for the applicable requirements before delivery. In this way, we ensure that your drive delivers what it promises in practice and over its entire life cycle. Everything is created completely in-house, without any dependence on third parties. Your advantage: We operate independently of global bottlenecks and can guarantee both quality and delivery times.

ContactOur rotary actuators in practice

Every application has different requirements – and we deliver the right movement.

Here you can see concrete solutions that set standards in practice.

Any questions about our rotary actuators?

We speak plainly.

About rotary actuators

We offer on-site installation and training for your employees on how to operate the system. Should unexpected challenges arise, our experts are quickly on site – for effective and lasting solutions.

Our rotary actuators are generally maintenance-free – thanks to high-quality workmanship and durable components. We will be happy to advise you on individual maintenance recommendations for special operating conditions.

We place the highest value on quality. If required, we test under realistic conditions – with intensive cycles and high loads. We coordinate quality and test characteristics individually with you.

We also ensure the availability of spare parts for drives that have been in use for a long time. Thanks to our in-house production, we can even manufacture spare parts for older motors. Availability is complemented by an extensive warehouse at our site in Bochum. Hense Systeme drives are designed for a long service life and reliability.

Depending on the application, we usually have suitable solutions available at short notice. The quickest way to clarify this is in a personal consultation.

We are happy to help you

Do you have any further questions?

Our service for you

We are here for youWe are there for our customers even before we produce a machine. We discuss the exact areas of application and use of the motors with you, taking into account your suggestions, requirements and experience. Once the motors have been commissioned, our service team can carry out regular maintenance or inspections on request and carry out any necessary repairs.

Learn moreGeneral information on rotary actuators.

A hydraulic rotary actuator converts the pressure and volume flow of a hydraulic system into a limited rotary movement. This usually takes place via a rotary vane, which is moved into a defined swivel position by the hydraulic pressure. The maximum swivel angle is specified by the design and is always less than 360 degrees.

Depending on the design or application, hydraulic rotary actuators are also referred to as rotary vane motors, rotary cylinders or rotary actuators. In English, terms such as “rotary actuator”, “swivel motor” or “hydraulic rotary drive” are commonly used.

With high-quality workmanship and a suitable design, hydraulic rotary actuators are extremely durable. Many models – including those from Hense Systeme – are generally maintenance-free. For special operating conditions, individual maintenance recommendations may be useful, which we will coordinate as part of our consultation.

Hydraulic rotary actuators are used wherever a limited rotary movement is required: e.g. for moving flaps, grippers, pallet changing systems, tool changing systems, or door stand technology. They can be found in mechanical engineering, automation, special plant engineering and many other industrial sectors.

A normal hydraulic motor generates a continuous rotary movement. Rotary actuators, on the other hand, are specially designed for limited angles of rotation and offer compact, high-torque solutions for precise, controlled swivel movements. They are easier to integrate and control – especially for recurring and fast, defined motion sequences.