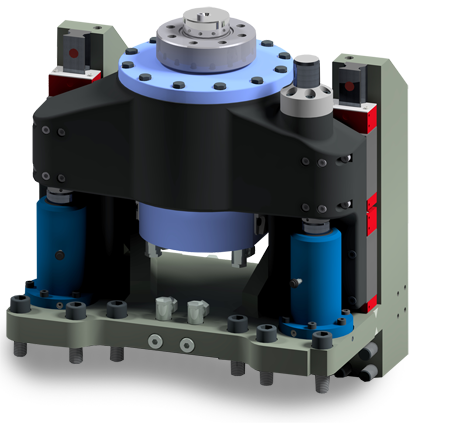

In principle, with the parallel arrangement, the vertically aligned rotary drive axis (rotary actuator) is placed next to the also vertically aligned linear drive axis, preferably consisting of two linear cylinders. The rotary actuator is inserted into a motor carrier separately mounted in linear guides and lifted along with it.

The pallet holder is mounted directly on the shaft of the rotary actuator or in a separate rotary bearing in the motor carrier. Tilting moments due to large asymmetrical loading conditions are thereby safely absorbed.

We offer customized solutions to suit various applications. Our qualified team will be happy to advise you.