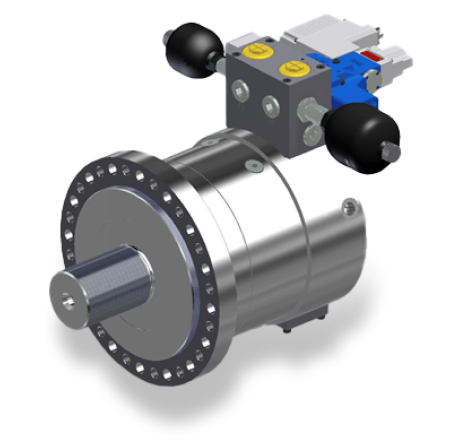

Our rotary actuator from the HSS series can be used for any installation position. Like all Hense rotary actuators, this rotary actuator is designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce internal motor friction, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections.

HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be implemented reliably and cost-effectively.

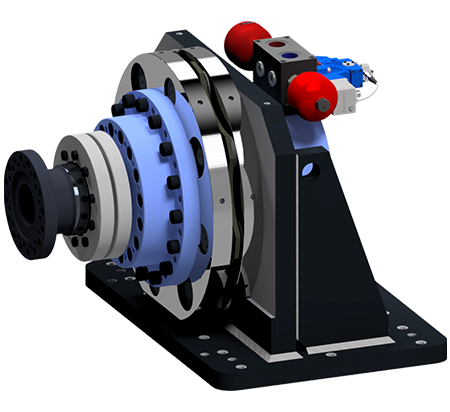

Servo-hydraulic hydraulic oscillator

In conjunction with other high-quality components, such as servo valves, pulsation accumulators and high-resolution angle measurement systems, the hydraulic oscillator is designed to generate alternating torsional loads.

We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.