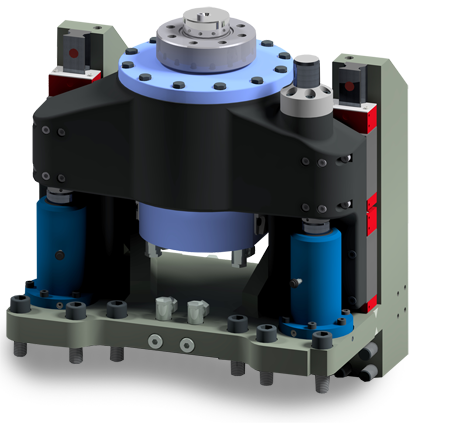

Pallet changing system

HUB rotary combinationHWP-Pallet changing

EXPERIENCE SINCE 1996Since 1996, we have been developing pallet changers with our rotary actuators for changing pallets with workpieces in machining centers.

The rotary actuator and linear unit of this pallet changer are designed so that all forces from the workpiece loading, even with one-sided pallet loading, are completely absorbed by the unit. The complex bearing points known from conventional changing systems are eliminated. Thus, a self-sufficient unit with extremely low assembly effort can be integrated into the machine bed and takes over the complete workpiece changing in the smallest of spaces. The wide acceptance of our system is proven by more than 8000 devices in 40 different variants, which have been delivered to 15 well-known machine tool manufacturers in the meantime.

The advantages at a glance:

- Compact unit with high power density

- Integrated bearing points to absorb all external forces from the workpiece changing, even with one-sided additional load

- Fast and harmonious kinematics

- Short downtimes due to fast workpiece changing

- Long service life with high reliability and freedom from maintenance

- High certified quality through extensive test runs of each pallet changer to be delivered on test benches

- Simplified logistics through product-specific transport frames

- Low product prices due to the elimination of proportional or servo valve technology

Parallel or serial

The basic principleIn the conception of a pallet changer, we distinguish between two design variants. In the so-called serial version, the lifting unit is placed on the drive shaft of the rotary actuator, which results in a long and slim design. In the second variant, the so-called parallel version, one or two lifting units are arranged parallel to the rotary actuator. This version requires a short and wide geometry. Which principle is used is largely determined by the selected overall structure of the machine tool, which ultimately dictates the available space between the machine bed and the floor or other components such as chip conveyors.

Product overview

We are happy to assist you with

individual advice

Do you have any further questions?