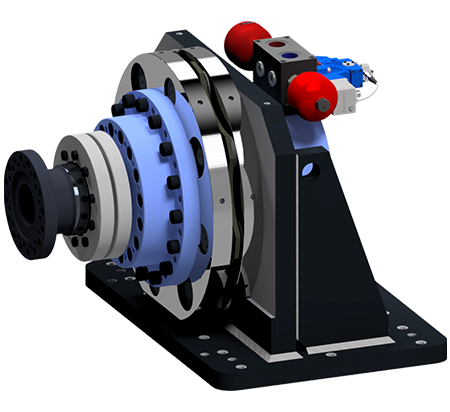

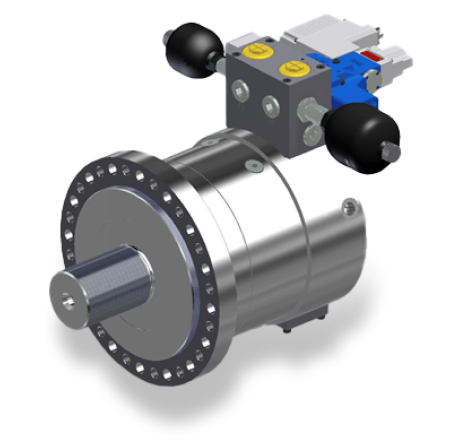

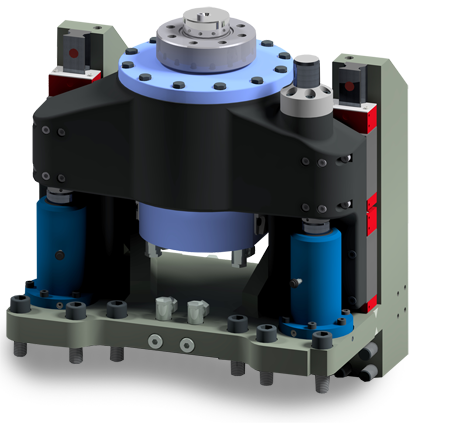

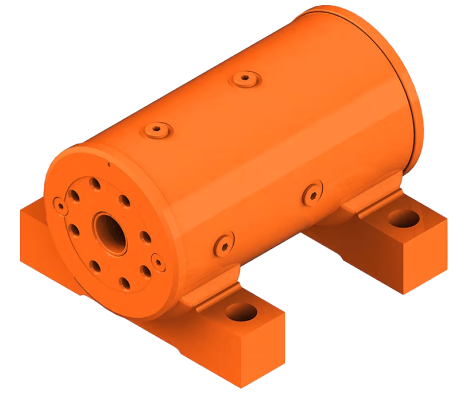

Our HSG series rotary actuator can be used for any installation position. In the HSG series, the rotary actuator has no end position damping or swivel angle limitation. Rotary actuators in this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The rotary actuators in this series are often also suitable in combination with simple hydraulic circuits if the inertial forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more.

In order to provide our customers with the right actuator for all areas of application, the HSG rotary actuator is available in a total of 11 different variants. We have listed the most important data below. All further details can be found in our data sheet.